Staalindustrieweg 43

2952 AT Alblasserdam

Tel: 078 - 681 85 68

Fax: 078 - 693 36 68

Email: info@ritmeester-bv.nl

WINDSCHERM TEAK WINDSCREEN

Windscherm, teak. Windscreen, teak.

It all starts with teakwood....

Meet the elephant at Royal Boogaerdt,

the pet animal of Wim Ista.

The owner of a very beautiful classic sailing yacht asked us to manufacture a teak windscreen in 5 parts for his yacht in refit.

After receiving the first set of preliminary moulds we met the owner and discussed both shape, angles and sizes of each part.

This is of course very important for the total ‘looks’ of the final result.

A number of changes were made to come to the best shape and ergonomics. Two more sets of templates were made. We visited the yacht and checked all the sizes, the curvature of the deck etc.

Sizes in relation to steering position were checked as well.

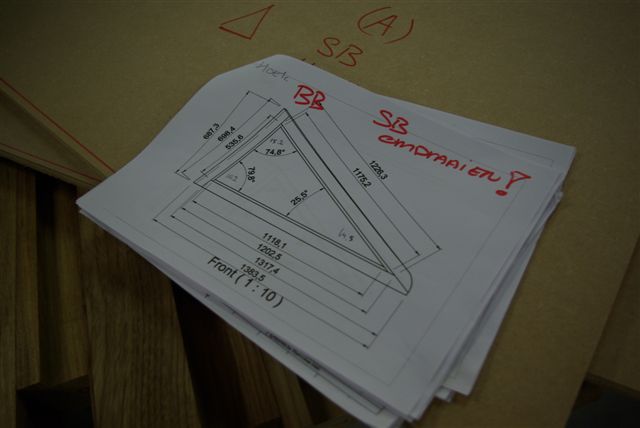

Then the total windscreen was drawn in 3-D in all parts. Also the five parts of the basis.

The selection of the teakwood followed as well as the machining of all parts. That’s ‘a whole lot of work’ because of the slanting and curved shapes. Many people don’t see through the enormous amount of machining and finishing steps to reach the final result.

We also supplied the hardened glass for the windscreen. It has to be certified for use at sea.

Finally the glass laths were supplied with a recess for the stainless steel inlays. The perfection lies in the details here also!

Pictures show you a small part of the manufacturing process.

For more information please see our contact details below. We can supply all windscreens: high quality and quick delivery. Also for repair and refit.

Please visit: www.ritmeester-bv.nl/nl/dept_245.html for more information

T: + 31 6 22 3 375 17

De eigenaar van een prachtig klassiek zeiljacht ‘in refit’ vroeg ons een vijfdelig windscherm in teakhout te maken.

Na onvangst van de eerste mallenset overlegden wij met de eigenaar omtrent zowel de totale vormen alsook omtrent ‘helling’ en de maten van elk deel.

Natuurlijk is dat van groot belang voor het totale beeld.

Een aantal wijzigingen werden aangebracht voor de beste vorm en ergonomie. Twee verdere mallensets werden vervaardigd. Wij bezochten het jacht waarbij alle maten gecontroleerd werden: de dekbolling ingemeten etc. De maten voor de stuurpositie werden ook gecontroleerd.

Het gehele windscherm werd vervolgens in 3-D getekend in alle delen; ook de 5 delen van de basis (fundatie).

De selectie van het teakhout volgde alsook het machineren van het hout voor alle delen. Dat is heel veel werk vanwege alle schuine hoeken en ronde vormen. Veel mensen doorgronden niet het enorme aantal handelingen van machineren en bewerken van het hout alsmede het afwerken om tot het definitieve resultaat te komen.

Wij leverden ook het gehard glad voor het windscherm. Dit moet gekeurd glas zijn voor gebruik op zee.

Ook de glaslatten met een sponning voor de roestvast stalen inlays werden op maat vervaardigd. De perfectie in elk detail schuilt overal.

Wij leveren alle soorten windschermen: hoge kwaliteit en snelle levering.

Ook voor reparatie, onderhoud, lakwerk zijn wij u graag en vakkundig van dienst.

Bezoek ook: www.ritmeester-bv.nl/nl/dept_245.html voor meer informatie.

It all starts with the right selection of teakwood.

Wim Ista is the professional at Royal Boogaerdt.

He is always friendly and very helpful.

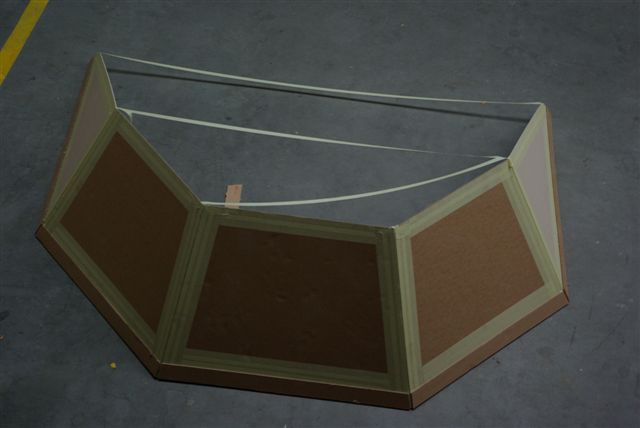

One of three mockups for the windscreen.

It always pays out to make a mockup for an existing yacht.

Especially when there is a refit and this is the first wooden windscreen

on the yacht.

With tape the first dimensions of the teakwood are indicated

(without the glass laths).

The mockup is checked onboard of the yacht

(No easy picture because of the low roof)

Sizes and also ergonomics are checked such as the view from te (secon) steering position

both standing and when sitting

Seen from behind, seated

Checking the angle of the side windows

View 'towards a Grand Banks'

Actual mockup of one window, with the basis (foundation) in white.

This was changed for the final version.

The glass laths also.

All elements are specified.

Templates are made for the glass for double security

Temepered Glass order is made with digital files

All parts are labeled and matched in grain

First image of how it is going to be... after more than one and a half week of work!

All angles are made and a digital measurement tool is very helpful for the best result

Of course the milling of the radiuses and the making of

custom made teakwood dominos is done also.

custom made teakwood dominos is done also.

Precision work.

Glueing parts. We use special glue: seawater resistant and high temperature resistant

Innovative clamping for the triangular windows...

Front:the basis for the windscreen windows.

Ant one of the triangular windows.

Ant one of the triangular windows.

Nearly ready, the glass laths are to be made.

As well as the curvature of the deck (in the basis)

As well as the curvature of the deck (in the basis)

The glass laths are shown here with the recess for the stainless steel inlay

specified by the owner.

The greenish color is typical for freshly sawn teakwood.

And the odor is lovely!

One example of the glass laths for the triangular side windows

Information/Informatie

T: +31 (0)6 22 33 75 17